Regulatory Oversight Report for Nuclear Power Generating Sites: 2019

Table of contents

- Executive summary

- 1 Introduction

-

2 General and supporting information

- 2.1 Management system

- 2.2 Human performance management

- 2.3 Operating performance

- 2.4 Safety analysis

- 2.5 Physical design

- 2.6 Fitness for service

- 2.7 Radiation protection

- 2.8 Conventional health and safety

- 2.9 Environmental protection

- 2.10 Emergency management and fire protection

- 2.11 Waste management

- 2.12 Security

- 2.13 Safeguards and non-proliferation

- 2.14 Packaging and transport

- 2.15 Other matters of regulatory interest

-

3 Nuclear power plant and waste management facility safety performance and regulatory developments

-

3.1 Darlington Nuclear Generating Station

- 3.1.0 Introduction

- 3.1.1 Management system

- 3.1.2 Human performance management

- 3.1.3 Operating performance

- 3.1.4 Safety analysis

- 3.1.5 Physical design

- 3.1.6 Fitness for service

- 3.1.7 Radiation protection

- 3.1.8 Conventional health and safety

- 3.1.9 Environmental protection

- 3.1.10 Emergency management and fire protection

- 3.1.11 Waste management

- 3.1.12 Security

- 3.1.13 Safeguards and non-proliferation

- 3.1.14 Packaging and transport

-

3.2 Darlington Waste Management Facility

- 3.2.0 Introduction

- 3.2.1 Management system

- 3.2.2 Human performance management

- 3.2.3 Operating performance

- 3.2.4 Safety analysis

- 3.2.5 Physical design

- 3.2.6 Fitness for service

- 3.2.7 Radiation protection

- 3.2.8 Conventional health and safety

- 3.2.9 Environmental protection

- 3.2.10 Emergency management and fire protection

- 3.2.11 Waste management

- 3.2.12 Security

- 3.2.13 Safeguards and non-proliferation

- 3.2.14 Packaging and transport

-

3.3 Pickering Nuclear Generating Station

- 3.3.0 Introduction

- 3.3.1 Management system

- 3.3.2 Human performance management

- 3.3.3 Operating performance

- 3.3.4 Safety analysis

- 3.3.5 Physical design

- 3.3.6 Fitness for service

- 3.3.7 Radiation protection

- 3.3.8 Conventional health and safety

- 3.3.9 Environmental protection

- 3.3.10 Emergency management and fire protection

- 3.3.11 Waste management

- 3.3.12 Security

- 3.3.13 Safeguards and non-proliferation

- 3.3.14 Packaging and transport

-

3.4 Pickering Waste Management Facility

- 3.4.0 Introduction

- 3.4.1 Management system

- 3.4.2 Human performance management

- 3.4.3 Operating performance

- 3.4.4 Safety analysis

- 3.4.5 Physical design

- 3.4.6 Fitness for service

- 3.4.7 Radiation protection

- 3.4.8 Conventional health and safety

- 3.4.9 Environmental protection

- 3.4.10 Emergency management and fire protection

- 3.4.11 Waste management

- 3.4.12 Security

- 3.4.13 Safeguards and non-proliferation

- 3.4.14 Packaging and transport

-

3.5 Bruce Nuclear Generating Station

- 3.5.0 Introduction

- 3.5.1 Management system

- 3.5.2 Human performance management

- 3.5.3 Operating performance

- 3.5.4 Safety analysis

- 3.5.5 Physical design

- 3.5.6 Fitness for service

- 3.5.7 Radiation protection

- 3.5.8 Conventional health and safety

- 3.5.9 Environmental protection

- 3.5.10 Emergency management and fire protection

- 3.5.11 Waste management

- 3.5.12 Security

- 3.5.13 Safeguards and non-proliferation

- 3.5.14 Packaging and transport

-

3.6 Western Waste Management Facility

- 3.6.0 Introduction

- 3.6.1 Management system

- 3.6.2 Human performance management

- 3.6.3 Operating performance

- 3.6.4 Safety analysis

- 3.6.5 Physical design

- 3.6.6 Fitness for service

- 3.6.7 Radiation protection

- 3.6.8 Conventional health and safety

- 3.6.9 Environmental protection

- 3.6.10 Emergency management and fire protection

- 3.6.11 Waste management

- 3.6.12 Security

- 3.6.13 Safeguards and non-proliferation

- 3.6.14 Packaging and transport

-

3.7 Point Lepreau Nuclear Generating Station

- 3.7.0 Introduction

- 3.7.1 Management system

- 3.7.2 Human performance management

- 3.7.3 Operating performance

- 3.7.4 Safety analysis

- 3.7.5 Physical design

- 3.7.6 Fitness for service

- 3.7.7 Radiation protection

- 3.7.8 Conventional health and safety

- 3.7.9 Environmental protection

- 3.7.10 Emergency management and fire protection

- 3.7.11 Waste management

- 3.7.12 Security

- 3.7.13 Safeguards and non-proliferation

- 3.7.14 Packaging and transport

-

3.8 Gentilly-2 Facilities

- 3.8.0 Introduction

- 3.8.1 Management system

- 3.8.2 Human performance management

- 3.8.3 Operating performance

- 3.8.4 Safety analysis

- 3.8.5 Physical design

- 3.8.6 Fitness for service

- 3.8.7 Radiation protection

- 3.8.8 Conventional health and safety

- 3.8.9 Environmental protection

- 3.8.10 Emergency management and fire protection

- 3.8.11 Waste management

- 3.8.12 Security

- 3.8.13 Safeguards and non-proliferation

- 3.8.14 Packaging and transport

-

3.1 Darlington Nuclear Generating Station

- 4 Conclusions

- 5 References

- A. Rating definitions and methodology

- A.1 Definitions

- A.2 Rating methodology – General approach

- A.3 Detailed description of steps in rating methodology

- B. List of regulatory requirements at the end of

- C. Current and predicted status of key parameters and models for pressure tubes in Canadian power reactor

- D. Derived release limits and radiological releases to the environment

- D.1 Darlington site

- D.2 Pickering site

- D.3 Bruce A and B

- D.4 Western Waste Management Facility

- D.5 Point Lepreau site

- D.6 Gentilly-2 Facilities

Executive summary

The regulatory oversight report describes the regulatory oversight and safety performance of nuclear power generating sites, consisting of nuclear power plants (NPPs) and adjacent waste management facilities (WMFs) in Canada in 2019. For certain topics, updates on developments in 2020 are also described. This is the third CNSC regulatory oversight report to cover both NPPs and WMFs.

Referenced documents in this regulatory oversight report are available to the public upon request.

The following list identifies the facilities for each site covered by this report. Each line in the list identifies facilities that are located at the same site and governed by a single CNSC licence; for this reason, they are assessed together in this report:

- Darlington Nuclear Generating Station (DNGS), which includes the Tritium Removal Facility and Retube Waste Processing Building

- Darlington Waste Management Facility (DWMF), which includes the Retube Waste Storage Building (RWOS-1)

- Pickering Nuclear Generating Station (PNGS)

- Pickering Waste Management Facility (PWMF)

- Bruce A Nuclear Generating Station and Bruce B Nuclear Generating Station

- Western Waste Management Facility (WWMF) and Radioactive Waste Operations Site-1

- Point Lepreau Nuclear Generating Station (PLNGS) and Solid Radioactive Waste Management Facility (SRWMF)

- Gentilly-2 Facilities

CNSC staff concluded that the NPPs and WMFs operated safely in 2019. This conclusion was based on detailed staff assessments of findings from compliance verification activities for each facility in the context of the 14 CNSC safety and control areas. The conclusion was supported by safety performance measures and other observations.

Important performance measures and observations include the following:

- The NPP and WMF licensees followed approved procedures and took appropriate corrective action for all events reported to the CNSC.

- NPPs and WMFs operated within the bounds of their operating policies and principles.

- No serious process failures occurred at the NPPs. The number of unplanned transients and trips in the reactors was low and acceptable to CNSC staff. All unplanned transients in the reactors were properly controlled and adequately managed.

- Radiation doses to the public were well below the regulatory limits.

- Radiation doses to workers at the NPPs and WMFs were also below the regulatory limits.

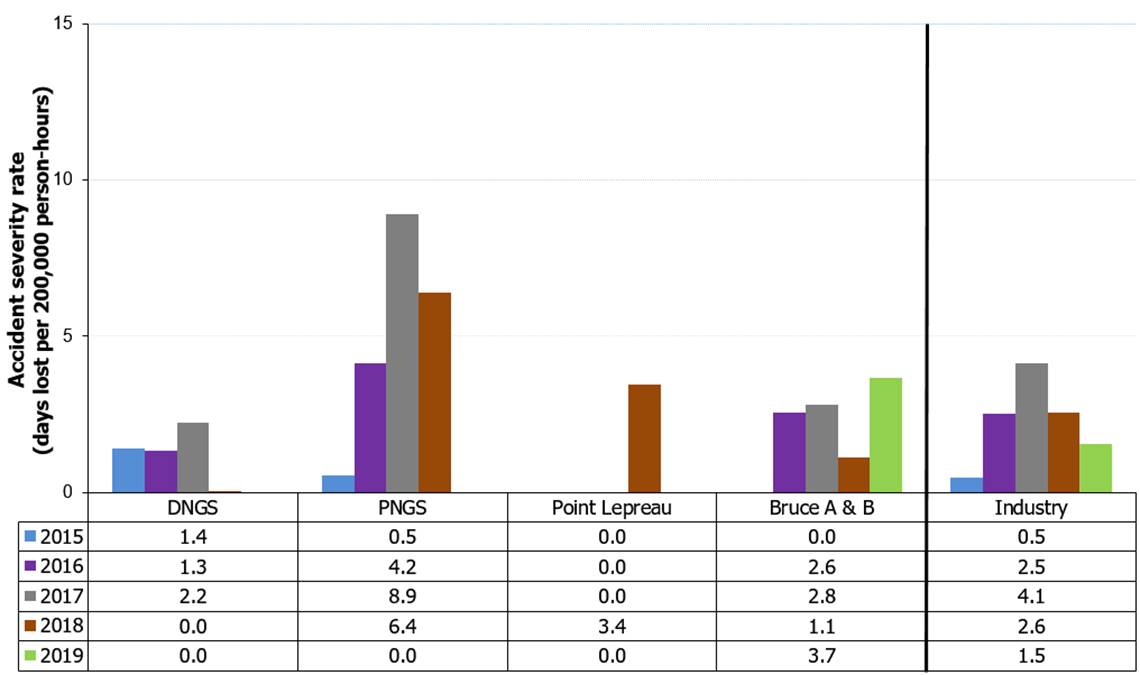

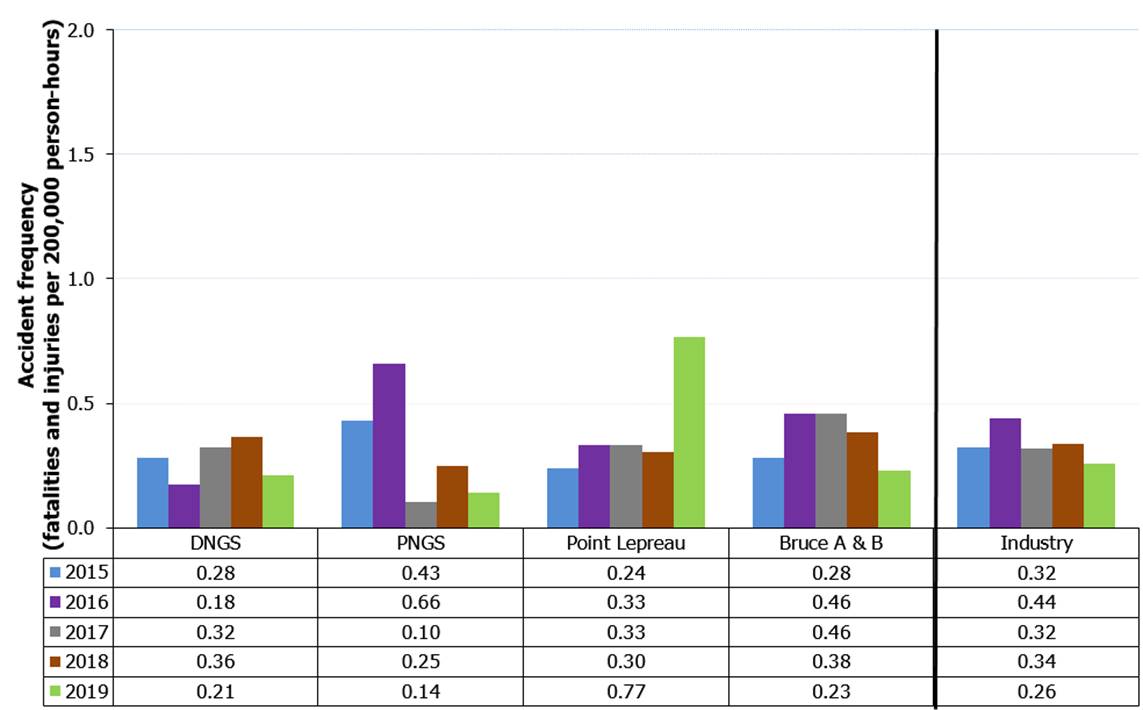

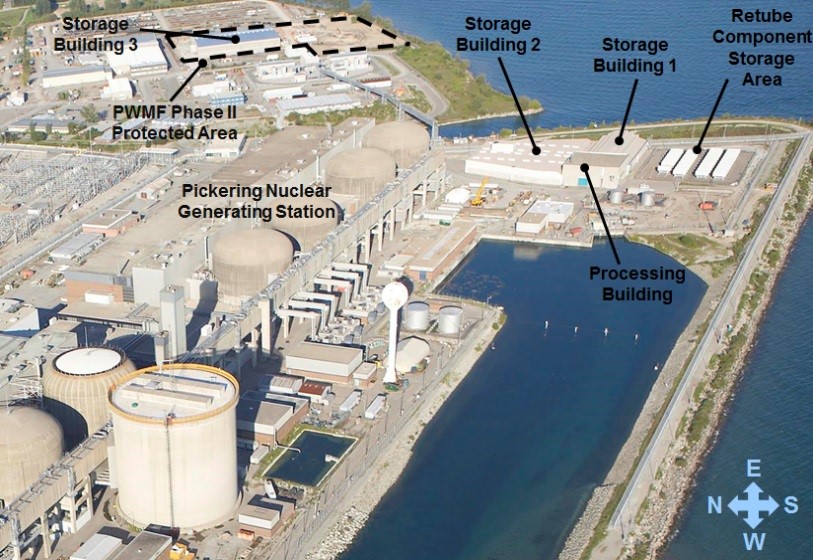

- The frequency and severity of non-radiological injuries to workers were low.

- No radiological releases to the environment from the NPPs and WMFs exceeded the regulatory limits.

- Licensees met the applicable requirements related to Canada’s international obligations; safeguards inspection results were acceptable to the IAEA.

CNSC staff’s assessments for 2019 concluded that the licensees complied with the applicable requirements and also met CNSC staff’s expectations for all SCAs at all the NPPs and WMFs.

1 Introduction

1.1 About the regulatory oversight report

The Regulatory Oversight Report for Canadian Nuclear Power Generating Sites: 2019 provides Canadian Nuclear Safety Commission (CNSC) staff’s assessment of the overall performance of Canadian nuclear power plants (NPPs) and their adjacent waste management facilities (WMFs) for 2019.

Section 1 of the report provides introductory material that explains this report, the licensed facilities that are covered, and the CNSC’s regulatory framework and practices.

Section 2 provides background information that serves as context for the assessments. Although the assessments for each site are provided in section 3, section 2 contains some assessments of groups of licensees, where appropriate. For example, section 2 compares safety performance data for multiple licensees.

Section 3 contains highlights from the individual assessments for each facility. The CNSC’s approach to the safety assessments of the NPPs and WMFs is described in section 1.4.5.

Sections 2 and 3 are organized according to the CNSC safety and control area (SCA) framework, as it existed at the end of 2019.

Section 4 contains CNSC staff’s conclusions based on the assessments presented in this report.

Some of the terms used in this document are defined in CNSC REGDOC-3.6, Glossary of CNSC Terminology.

This report includes information requested by the Commission from previous regulatory oversight reports and licensing hearings. These requests are tracked through the CNSC’s Regulatory Information Bank (RIB) system. Table 1 provides the RIB tracking number, a description of the request, and where the request is addressed by CNSC staff in this report, as applicable.

| RIB # | Request | Report section |

|---|---|---|

| 17560 | Include data for total recordable injury frequency for all workers, including contractors, if it is available | 2.8 |

| 17557 |

Follow-up to the licence renewal for Pickering Nuclear Generating Station (PNGS)

|

3.3.0 2.4, 3.3.4 2.6 |

| 17522 |

Provide update on emergency management and preparedness at the PNGS

|

2.10 |

| 16516 |

Provide update on the PNGS fish diversion system

|

3.3.0 3.3.9 a) 3.3.0 b) 2.15 |

| 14761 | Describe enhancements at Bruce A to bring internal fire risk below the safety goal target | 3.5.4 |

| 14760 | Monitor Bruce Power’s work to perform site-wide PSA for the next licence renewal | 2.4, 3.5.4 |

| 14759 | Report on Bruce Power’s progress on providing aggregate risk values for the next licence renewal. (The Commission made this request following the 2018 Bruce A and B licence renewal hearing.) | 2.4, 3.5.4 |

| 14757 |

Describe developments related to pressure tube fracture toughness for Bruce A and B, including:

|

2.6, 3.5.6 |

| 14755 | Provide update on the implementation of automated data transfer from Bruce A and B to the CNSC Emergency Operations Centre | 3.5.10 |

| 14753 | Provide update on status of major component replacement for Bruce A and B | 3.5.0 |

| 8504 | Provide update on the CNSC’s regulatory position on risk aggregation | 2.4 |

1.2 Scope of the regulatory oversight report

The scope of this 2019 regulatory oversight report is similar to that of the Regulatory Oversight Report for Canadian Nuclear Power Generating Sites: 2018 [2]. The 2019 report covers the NPPs in Canada, including Gentilly-2 Facilities. General statements in the report that refer to “NPPs” are intended to apply to the Gentilly-2 Facilities, while the phrase “operating NPPs” is used for statements that do not apply to the Gentilly-2 Facilities. The report also covers the WMFs located at the same sites, whether they are regulated under the same licence as the NPP or licensed separately.

Generally speaking, the information provided in this regulatory oversight report is pertinent to 2019, and the status that is described is valid as of December 2019. The word “UPDATE” is used to identify topics where more recent information (up to June 1, 2020) is included (for example, progress on corrective actions, descriptions of significant events and updates that the Commission specifically requested).

The detailed scope of the safety assessments in this regulatory oversight report is covered by the set of specific areas that constitute each SCA. They are described in more detail in General Description of Regulatory Framework for Nuclear Power Generating Sites [1]. As noted in that document, some specific areas do not apply to the Gentilly-2 Facilities and the WMFs. Therefore, those areas were not considered in the safety assessments for those facilities.

1.3 Nuclear facilities covered by this regulatory oversight report

Figure 1 shows the geographic location in Canada of the NPPs and WMFs covered by this report. All sites are located on traditional territories of Indigenous peoples in Canada.

1.3.1 Nuclear power generating sites and associated waste management facilities in Canada

The Darlington site is located in Clarington, Ontario, and consists of the Darlington Nuclear Generating Station (DNGS) and the Darlington Waste Management Facility (DWMF). The DNGS and DWMF are licensed separately. See sections 3.1 and 3.2 for details. The site also includes the Darlington New Nuclear Project (DNNP).

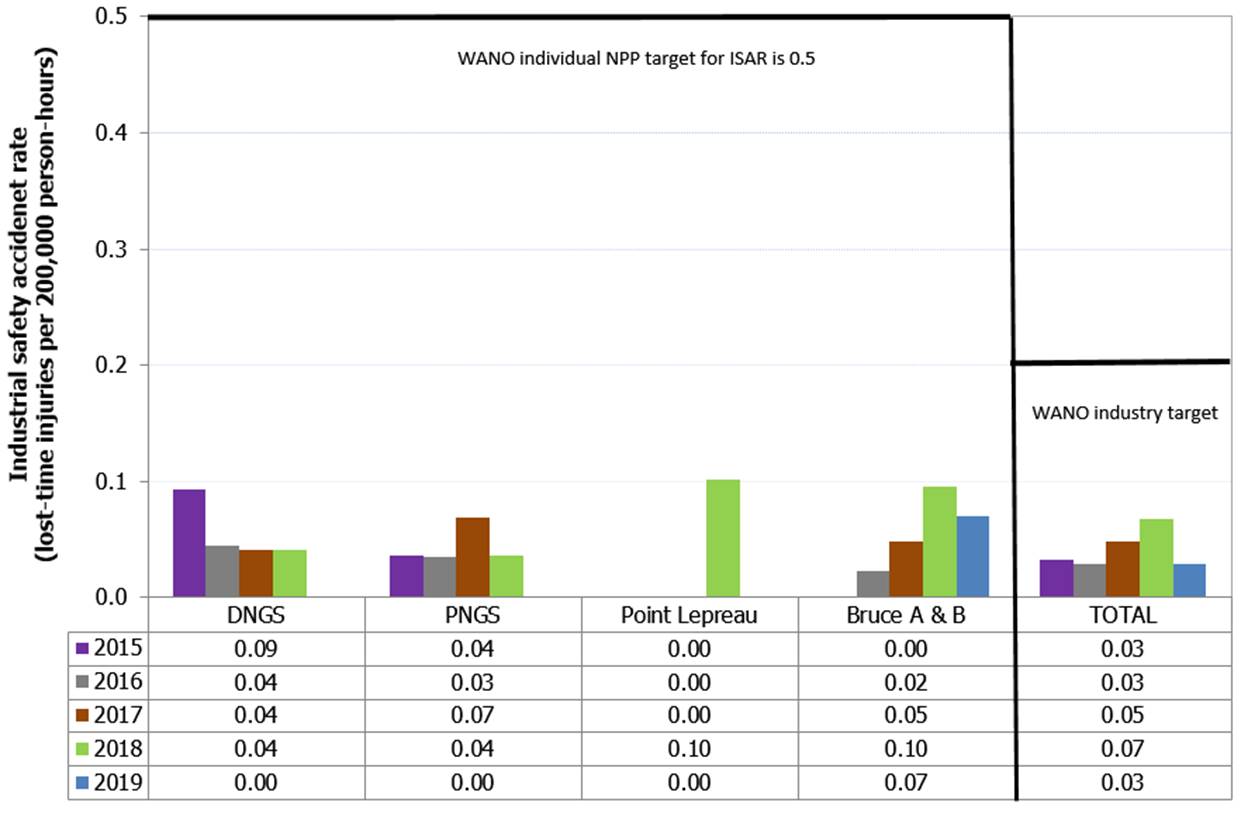

The Pickering site is located in Pickering, Ontario, and consists of the Pickering Nuclear Generating Station (PNGS) and the Pickering Waste Management Facility (PWMF). The PNGS and the PWMF are licensed separately. See sections 3.3 and 3.4 for details.

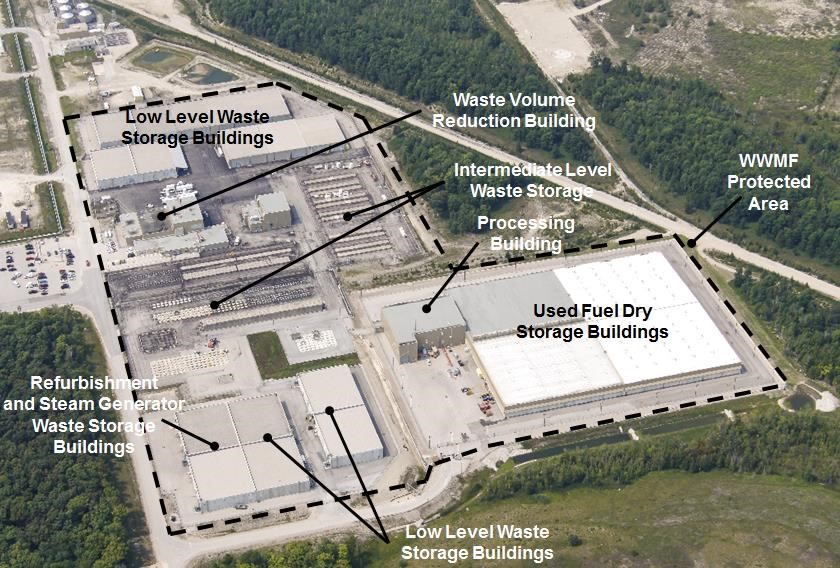

The Bruce site is located in Tiverton, Ontario, and consists of the Bruce A and B Nuclear Generating Stations; OPG’s Western Waste Management Facility (WWMF) and Radioactive Waste Operations Site-1 (RWOS-1); and Canadian Nuclear Laboratory’s (CNL’s) Douglas Point Waste Facility. Bruce A and B are licensed together. The WWMF, RWOS-1 and Douglas Point Waste Facility are each licensed separately. See sections 3.5 and 3.6 for details. Note that the Douglas Point Waste Facility is not covered in this report, but in the Regulatory Oversight Report for Canadian Nuclear Laboratories Sites: 2019.

The Point Lepreau site is located on the Lepreau Peninsula in New Brunswick and consists of the Point Lepreau Nuclear Generating Station (PLNGS) and the Solid Radioactive Waste Management Facility (SRWMF). The operations of PLNGS and the SRWMF are authorized under a single licence. See section 3.7 for details.

The Gentilly nuclear site is located in Bécancour, Quebec, and consists of CNL’s Gentilly-1 Waste Facility and Hydro-Québec’s Gentilly-2 Facilities. The Gentilly‑1 and Gentilly-2 facilities are licensed separately. See section 3.8 for details. Note that the Gentilly-1 Waste Facility is not covered in this report, but in the Progress Update for CNL’s Prototype Waste Facilities, Whiteshell Laboratories and the Port Hope Area Initiative.

1.3.2 Nuclear power plants

Figure 2 provides data for each NPP, including the generating capacity of the reactor units, their initial start-up dates, and reactor status in 2019. See section 3 for additional information on the NPPs and licences.

.jpg/object)

Operating NPPs

Eighteen reactors continued to operate in Canada throughout 2019. They are located at 4 NPP sites, each with a power reactor operating licence (PROL) issued by the CNSC. They are located in 2 provinces (Ontario and New Brunswick) and are operated by 3 distinct licensees (OPG, Bruce Power and NB Power). These NPPs range in size from 1 to 8 power reactors, all of which are of the CANDU (CANada Deuterium Uranium) design.

Non-operating reactors and NPP

As noted in figure 2, the DNGS includes Unit 2, which was being refurbished in 2019 and did not operate. The PNGS also includes Units 2 and 3, which remained defueled and in safe storage. They are also governed by the same PROL as the operating units.

In addition, the NPP at the Gentilly-2 Facilities is shut down and is proceeding to decommissioning. It is also governed by a power reactor decommissioning licence.

New NPPs

In 2012, the Commission issued a 10-year nuclear power reactor site preparation licence (PRSL) to OPG for the Darlington New Nuclear Project at the Darlington site. The PRSL requires OPG to continue follow-up work on the environmental assessment (EA) conducted in conjunction with the licence application.

UPDATE: OPG submitted its application to renew the PRSL in June 2020.

1.3.3 Waste management facilities

The WMFs that are assessed separately in this regulatory oversight report are the ones that are licensed independently from the adjacent NPP. They include the DWMF, PWMF and WWMF, each of which is owned and operated by OPG under a waste facility operating licence (WFOL).

Table 2 provides data for each WMF, including the initial start-up date, the name of the licensee, the expiry date of the licence, and the type of waste managed at each facility (for example, low- and intermediate-level waste (L&ILW), intermediate-level waste (ILW) and high-level waste (HLW)). See section 3 for additional information on the facilities and licences.

As discussed in section 1.3.1, both the Point Lepreau and Gentilly-2 sites also have WMFs.

| Facility | Licensee | Operation start | WFOL expiry | Manages |

|---|---|---|---|---|

| DWMF | OPG | 2008 | Apr 30, 2023 |

HLW from DNGS ILW from DNGS refurbishment |

| PWMF | OPG | 1996 | Aug 31, 2028 |

HLW from PNGS ILW from PNGS Units 1–4 refurbishment |

| WWMF | OPG | 1974 | May 31, 2027 |

HLW from Bruce A and B NPPs ILW from Bruce Units 1 and 2 refurbishment L&ILW from DNGS, PNGS, and Bruce A and B operations |

| RWOS-1 | OPG | Mid-1960 | Oct 31, 2029 | L&ILW from Douglas Point WMF and PNGS |

1.4 Regulatory framework and oversight

The CNSC regulates the nuclear sector in Canada, including NPPs and WMFs, through licensing, reporting, compliance verification, and enforcement. The CNSC uses a risk-informed regulatory approach, applying resources and regulatory oversight commensurate with the risk associated with the regulated facility and activity. Additional information on the CNSC regulatory framework and oversight is provided in this section and in General Description of Regulatory Framework for Nuclear Power Generating Sites [1].

1.4.1 CNSC requirements

All licensees are required to operate in accordance with the licensing basis. The licensing basis is defined in CNSC REGDOC-3.5.3, Regulatory Fundamentals, and comprises the following:

- the regulatory requirements set out in the applicable laws and regulations

- the conditions and safety and control measures described in the facility’s or activity’s licence and the documents directly referenced in that licence

- the safety and control measures described in the licence application and the documents needed to support that licence application

The requirements in parts (ii) and (iii) of the licensing basis are unique to each licensed facility – they depend on the content of a given licence, licence application and the applicant’s supporting documentation. Regulations made under the Nuclear Safety and Control Act (NSCA), including the Class I Nuclear Facilities Regulations, provide requirements on the content of licence applications for NPPs and WMFs.

Licence applications for NPPs and WMFs cite CNSC regulatory documents, CSA Group standards, and other publications, as well as the applicant’s own documentation. When a licence is issued, CNSC staff develop a licence conditions handbook (LCH) to identify the specific requirements that apply to that licence. All NPPs and WMFs covered by this report have LCHs.

Appendix B lists all CNSC regulatory documents and CSA Group standards that are identified as containing compliance verification criteria in the LCHs for the NPPs and WMFs covered by this regulatory oversight report. The appendix illustrates the large number of CNSC regulatory documents and CSA Group standards that provide requirements relevant to all SCAs.

Appendix B also indicates the significant number of newer CNSC regulatory documents and CSA Group standards that the licensees are implementing. Details about the implementation of these publications are provided under the relevant SCAs throughout this regulatory oversight report.

In this report, CNSC regulatory documents typically start with “REGDOC-” followed by an identifying number. CSA Group standards are typically identified by “CSA N.xxx” where xxx is the number of the publication.

Each licensee implements new CNSC regulatory documents and CSA Group standards in a staged, risk-informed manner that takes into consideration the timing of licence renewals, operational needs, and other concurrent changes. Although differences exist in applicable requirements between similar facilities at any given time, the requirements nevertheless are comprehensive, and improved requirements are implemented in a measured and systematic way.

1.4.2 Licensing

The Commission has granted a licence to each of the operating NPPs and WMFs described in this report. The typical period for a WFOL and a PROL has been 10 years and 5 years, respectively, while Hydro-Québec has a 10-year licence to decommission its power reactor. In 2015, the Commission granted OPG a 10-year licence for the DNGS. In 2018, the Commission granted Bruce Power a 10-year licence for Bruce A and B and granted OPG a 10-year licence for the PNGS. For operating NPPs, this longer licence is issued in conjunction with the implementation of a periodic safety review (PSR) process in preparation for the next licence renewal.

The PSR is a comprehensive evaluation of the design, condition and operation of an NPP. As outlined in CNSC REGDOC-2.3.3, Periodic Safety Reviews, a PSR involves an assessment of the current state of the NPP and plant performance to determine the extent to which the NPP conforms to modern codes, standards and practices, and to identify any factors that would limit safe, long-term operation. The PSR provides the licensee a framework to systematically identify practicable safety enhancements, which are documented in an integrated implementation plan (IIP). For operating NPPs, licence conditions have been used to require the licensee to implement the IIP during the licence period and to conduct a PSR in support of the next licence renewal. A PSR is not a requirement for the Gentilly-2 Facilities or the WMFs because the associated hazards are relatively smaller and the requirements change relatively slowly. For these reasons, the regular licensing process and implementation of CNSC regulatory documents and CSA Group standards are sufficient to assure safe, long-term operation.

Section 3 describes the status of the PSR for each operating NPP.

Fisheries Act authorizations

In addition to CNSC licences, this regulatory oversight report describes developments related to Fisheries Act authorizations. The Fisheries Act requires the establishment of offsets to compensate for any residual harm caused to fish and fish habitats after mitigation measures have been put in place. The CNSC has a memorandum of understanding with Fisheries and Oceans Canada whereby CNSC staff are responsible for monitoring activities and verifying compliance for Fisheries Act authorizations. The Minister of Fisheries and Oceans Canada is responsible for enforcing the authorizations in the event of non-compliance.

1.4.3 Reporting

Licensees are required to provide various reports and notices to the CNSC in accordance with regulations made under the NSCA. LCHs clarify CNSC expectations for these requirements, if needed.

In addition to, and in conjunction with, the reporting requirements in the regulations, a licence condition requires NPP licensees to report to the CNSC in accordance with CNSC REGDOC‑3.1.1, Reporting Requirements for Nuclear Power Plants. REGDOC-3.1.1 requires licensees to submit quarterly and annual reports on various subjects; for example, quarterly reports on the safety performance indicators that are discussed in this report. REGDOC-3.1.1 also provides detailed requirements related to the submission of other important reports (such as updates to the final safety analysis report, proposed decommissioning plan and annual environmental protection report). REGDOC‑3.1.1 also requires licensees to report any unplanned situations and events to the CNSC.

For the Gentilly-2 Facilities, the requirements in REGDOC-3.1.1 have been adjusted in accordance with its current state and the associated risks [5].

During 2019, NPP licensees reported to CNSC staff on 217 events and submitted 90 scheduled reports. In accordance with the General Nuclear Safety and Control Regulations, WMF licensees also submitted 8 reports to CNSC staff for reportable events that occurred at the DWMF, PWMF and WWMF.

The CNSC published REGDOC-3.1.2, Reporting Requirements, Volume I: Non-Power Reactor Class I Facilities and Uranium Mines and Mills, in January 2018. Beginning in 2019, the WMFs reported to the CNSC in accordance with REGDOC-3.1.2.

1.4.4 Compliance verification program

The safety assessments presented in this report were based on the results of activities planned through the CNSC compliance verification program (CVP). In 2019, these activities included Type II inspections that evaluate the outputs and outcomes of licensee programs; field inspections that collect data on the outputs and outcomes of licensee programs; desktop inspections and reviews; and surveillance and monitoring.

Additional reactive CVP activities for NPPs and WMFs are added as needed. These focus on site-specific matters and known or potential licensee challenges. CNSC staff then validate the annual plans by using a risk-informed approach that considers the status, performance history, and conditions and challenges of each facility, to ensure appropriate regulatory oversight and safety performance evaluation. More CVP activities for NPPs and WMFs may also be added during the year in response to new or emerging licensee challenges. The goal is to ensure that the CVPs for NPPs and WMFs are always timely, risk-informed, performance-based and responsive to developments.

The CVPs for NPPs also include desktop reviews of safety performance indicators submitted quarterly to the CNSC in accordance with REGDOC-3.1.1. This regulatory oversight report reproduces data for some of these indicators. No regulatory limits or thresholds are associated with this data, but CNSC staff monitor the data, watching for trends over time and deviations from the data typically provided by other licensees with similar operations or facilities. CNSC staff follow any unfavourable trend or comparison by increased regulatory scrutiny, which can range from increased surveillance and monitoring, to increased focus during field inspections, adjustment of the timing or scope of a baseline inspection, a focused desktop review or a reactive inspection, depending on the safety significance of the trend or deviation.

1.4.5 Safety assessment ratings

This report presents safety performance ratings for each SCA at each NPP and WMF based on findings generated during CVP activities. All findings are categorized into appropriate SCAs and specific areas and assessed against a set of high-level performance objectives for the SCAs, as well as the detailed regulatory requirements and CNSC staff’s performance expectations. Since the CVP consists of a rolling (typically 5-year) cycle of regulatory activities, not all specific areas are directly evaluated every year.

The SCAs and specific areas are described in more detail in General Description of Regulatory Framework for Nuclear Power Generating Sites [1]. See appendix A for a description of the rating methodology used for this regulatory oversight report.

In generating the ratings, CNSC staff considered 1,475 findings for NPPs and 145 for WMFs in 2019. All but 2 of these findings were assessed as being either compliant or of negligible or low safety significance. In other words, they had a positive, insignificant or small negative impact on safety within the specific area. Sections 3.2.10 and 3.6.14 discuss the 2 “medium” findings that had significant negative effects in the context of the assessment of their respective specific areas.

For the Bruce site,Footnote 1 Bruce A and B are rated separately from the WWMF because they are operated by different licensees. For the Darlington and Pickering sites, the NPP and WMF are rated separately because they are regulated under separate licences and have facility-specific licensing bases. The WMFs at the Point Lepreau and Gentilly-2 sites are governed by the NPP licences and are subject to the same regulatory requirements, so they are assessed together with their respective NPPs (as was done in previous regulatory oversight reports).

1.4.6 Update on CNSC COVID-19 response and related NPP oversight

On March 15, 2020, the CNSC activated its Business Continuity Plan, in response to the COVID-19 pandemic. Effective March 16, all CNSC staff in Ottawa and at regional and site offices were directed to work from home. CNSC management immediately suspended all regular NPP and WMF compliance verification activities and identified activities that were considered critical, in order to support continued safe power reactor operation and regulatory decision making. For example, oversight activities and reviews related to the release of regulatory hold points for Darlington Unit 2 were carried out remotely with no interruption, in adherence to measures put in place by CNSC management, OPG and federal and provincial authorities.

In April 2020, CNSC management approved a new procedure for planning and conducting compliance verification activities at NPPs, to ensure continued regulatory oversight during the COVID-19 pandemic. This procedure was and is to be utilized during and following the pandemic for fiscal year 2020/21 until normal compliance processes resume. The procedure provides a framework and direction for the conduct of oversight activities both remote and onsite, as well as direction on revising the annual compliance plan for this fiscal year (2020–21).

The framework also allows for enhancing the number and capabilities of site inspectors to work remotely. CNSC staff have worked with licensees to obtain comprehensive and remote access to site information systems, actual plant data and participation in all key plant management meetings.

In addition to this new procedure, CNSC staff developed a pandemic-related pre-job brief as additional instructions for site office supervisors to deliver to site inspectors before they perform onsite oversight activities. Provision of personal protective equipment (PPE) to site inspectors prior to any onsite activities forms part of this pre-job brief.

In May 2020, onsite oversight activities resumed at NPPs in a limited capacity. These activities focused on general health and safety issues (such as control of combustible material, housekeeping and contamination posting), as well as licensee adherence to their pandemic response plans and COVID-19 health protocols. As part of its precautions, the CNSC is managing and limiting site inspectors’ access to the site offices and providing additional PPE and sanitization products.

CNSC staff continue to conduct oversight activities during the COVID-19 pandemic to ensure the protection of the environment, and the health and safety of people. Oversight activities completed in 2020 during the pandemic will be further described in the 2020 regulatory oversight report.

2 General and supporting information

This section provides information, organized by safety and control area (SCA), which serves as background for the assessments in section 3. In some cases, it describes and assesses data and issues that apply to more than one facility. The subsections are organized according to the specific areas of each SCA, although some specific areas are omitted if there is no new information. General information about the SCAs and the applicability of the specific areas is provided in General Description of Regulatory Framework for Nuclear Power Generating Sites [1].

2.1 Management system

Safety culture

The CNSC published REGDOC-2.1.2, Safety Culture, in April 2018. This document sets out requirements and guidance for the licensee to foster a healthy safety culture and conduct periodic safety culture assessments. NPP licensees provided implementation plans for REGDOC-2.1.2 in 2019. The CNSC confirmed that Hydro-Québec complied with this regulatory document. As part of their implementation work, OPG, Bruce Power and NB Power made commitments to conduct their next self-assessments in accordance with REGDOC‑2.1.2.

Additionally, most NPP licensees have implemented safety culture monitoring panels following the guidance provided by the Nuclear Energy Institute.

Management of contractors

In 2019, NPP licensees reported events related to the topic of counterfeit, fraudulent and suspect items (CFSIs, e.g., as discussed in section 3.3.1 for the PNGS). For the most part, the licensee processes for detection of suspect or counterfeit items have been effective. The particular concern about the reported events was the misrepresentation of product or service quality early in the supply chain (that is, fraudulence), which is difficult to detect. This has been more of a concern in the global context than in Canada. Nonetheless, noting that fraudulence can be detected with improved oversight of suppliers, CNSC staff continued to focus on the licensees’ supply chains, with particular attention to fraudulence. CNSC staff were planning improved oversight activities in early 2021.

Business continuity

All licensees have business continuity plans that would be activated in the case of a labour disruption, major external event, or pandemic.

2.2 Human performance management

Human performance program

CNSC staff’s inspection activities in 2019 indicated that the NPP and WMF licensees were developing and expanding their human performance programs to consider a systemic approach that includes the interactions of humans, technology and the organization to support worker performance. The licensees were increasing their focus on accountability of workers and on learning from events in order to improve human performance.

Personnel certification

Each NPP licence has a condition that requires the licensee to have certified personnel in specific positions. All NPPs have certification requirements for responsible health physicists, and the operating NPPs are also required to have certified shift supervisors, shift managers and reactor operators. Due to the design of Bruce A, Bruce B and the DNGS, the CNSC requires those licensees to also employ certified Unit 0 operators.

Table 3 shows the number of certified personnel who were available in the certified positions at each NPP, as of December 31, 2019. The table also shows the minimum required number of personnel for each position, which is the minimum number of certified personnel that must be present at all times multiplied by the total number of crews.

| Station | Reactor operator | Unit 0 operators a | Shift supervisor b | Health physicist | Total |

|---|---|---|---|---|---|

| DNGS | |||||

| Actual | 64 | 18 | 32 | 5 | 119 |

| Minimum | 30 | 10 | 10 | 1 | 51 |

| PNGS Units 1 and 4 | |||||

| Actual | 42 | 21 | 2 c | 66 | |

| Minimum | 20 | 10 | 1 | 31 | |

| PNGS Units 5–8 | |||||

| Actual | 64 | 20 | 2 c | 87 | |

| Minimum | 30 | 10 | 1 | 41 | |

| Bruce A | |||||

| Actual | 49 | 23 | 23 | 4 d | 99 |

| Minimum | 30 | 10 | 10 | 1 | 51 |

| Bruce B | |||||

| Actual | 62 | 22 | 23 | 4 d | 111 |

| Minimum | 30 | 10 | 10 | 1 | 51 |

| Point Lepreau | |||||

| Actual | 9 | 7 | 2 | 18 | |

| Minimum | 6 | 6 | 1 | 13 | |

| Gentilly-2 e | |||||

| Actual | 2 | 2 | |||

| Minimum | 1 | 1 | |||

- There are no Unit 0 positions at PNGS Units 1 and 4 and Units 5–8, or Point Lepreau.

- At multi-unit NPPs, the shift supervisor number is the total of certified shift managers plus certified control room shift supervisors.

- There are 2 certified health physicists in all at Pickering, who cover both PNGS Units 1 and 4 and Units 5–8.

- There are 4 certified health physicists in all at Bruce, who cover both Bruce A and Bruce B.

- There are no reactor operators, Unit 0 operators or shift supervisors at Gentilly-2.

Initial certification examinations and requalification tests

As noted above, health physicists are the only certified personnel employed at the Gentilly-2 Facilities. Since CNSC staff administer the initial examinations and requalification tests of the health physicists for Hydro-Québec, this specific area does not apply to the Gentilly-2 Facilities. There are no certified personnel at the WMFs.

Work organization and job design

All NPP licensees have a documented minimum shift complement (MSC), which forms part of its licensing basis. The MSC is monitored each shift and is managed through face-to-face turnover, the use of electronic minimum complement monitoring systems, or the use of whiteboards that track personnel in and out of the facility.

In 2019, licensees reported 1 MSC violation at the DNGS, 2 violations at the PNGS, 1 violation at Bruce A and B and 3 violations at Point Lepreau. All violations were of a short duration and the licensees took appropriate actions; for example, calling in relief personnel, holding over personnel already present and operating in quiet mode.

Fitness for duty

CNSC oversight of fitness for duty includes assessments of licensee measures related to managing worker fatigue; the management of alcohol and drug use; and minimum requirements for medical, physical and psychological certificates for nuclear security officers.

Managing worker fatigue

All NPP licensees have procedures to manage worker fatigue. The procedures include limits on hours of work.

CNSC REGDOC-2.2.4, Fitness for Duty: Managing Worker Fatigue, specifies requirements and guidance for managing worker fatigue at all high-security si.tes, with the aim of minimizing the potential for errors that could affect nuclear safety and security. OPG, Bruce Power and Hydro-Québec implemented this regulatory document in 2019, while NB Power planned to implement the document by 2020 for normal operations and 2022 for outages. NB Power’s plan involved expanding its security and emergency response team personnel (to a 6-crew format working on a 42-day shift cycle, which would match its operations personnel).

Type I inspections to confirm compliance with REGDOC-2.2.4 were planned in 2020 for OPG and Bruce Power.

UPDATE: In May 2020, NB Power informed the CNSC of a revision to its implementation plan, resulting in a planned implementation for operations by April 2021. CNSC staff reviewed the revised implementation plan and found it acceptable.

Managing alcohol and drug use

REGDOC-2.2.4, Fitness for Duty, Volume II: Managing Alcohol and Drug Use, sets out requirements and guidance for managing fitness for duty of workers occupying safety-sensitive and safety-critical positions in relation to alcohol and drug use at all high-security sites. All licensees of high-security sites provided implementation plans early in 2018, which CNSC staff accepted. In late 2018, OPG, Bruce Power and NB Power requested an amendment, in order to include oral fluid testing to supplement the urinalysis required by the regulatory document. OPG, Bruce Power and NB Power requested a change to their implementation dates, proposing to implement REGDOC‑2.2.4, Volume II within a period following the date of its amendment (or from the date it is determined that it will not be amended). Specifically, the licensees proposed to implement the requirements other than random testing within 6 months of that date and to implement random testing within 12 months of that date. CNSC staff reviewed and accepted the request and began work in 2019 to revise REGDOC-2.2.4, Volume II.

Hydro-Québec implemented the current version of REGDOC-2.2.4, Volume II in July 2019.

CNSC staff anticipated the amended regulatory document will be submitted to the Commission for approval in 2020.

Nuclear security officer medical, physical and psychological fitness

Licensees are required to ensure that all nuclear security officers have medical, physical and psychological certificates that meet the CNSC’s requirements. CNSC REGDOC-2.2.4, Fitness for Duty, Volume III: Nuclear Security Officer Medical, Physical and Psychological Fitness, sets out the expectations and minimum requirements for these certificates. All licensees have made a commitment to fully implement the document by December 31, 2020.

2.3 Operating performance

Conduct of licensed activity

Eighteen reactors continued to operate in Canada throughout 2019, along with the WMFs at the same sites. Unit 2 at Darlington was shut down in 2019 while refurbishment continued.

The licensees’ quarterly reports for operating NPPs include data on the safety performance indicator for the number of unplanned transients, which tracks unplanned transients (unexpected reactor power reductions) for each reactor that is not in a guaranteed shutdown state. Unplanned transients indicate problems within a plant and place unnecessary strain on its systems.

Table 4 summarizes the number of unplanned transients for the operating NPPs (specifically setbacks, stepbacks and reactor trips,Footnote 2). The last row, “Industry total,” provides the data for the operating NPPs as a whole. In 2019, all unplanned transients were properly controlled and adequately initiated by the reactor control systems. CNSC staff also determined that no serious process failures occurred at any NPP in 2019.

| NPP | Number of operating reactors | Number of hours of operation | Trips | Stepbacks | Setbacks | Total unplanned transients | Number of trips per 7,000 operating hours |

|---|---|---|---|---|---|---|---|

| DNGS | 3 | 23,521 | 0 | 0 | 1 | 1 | 0.00 |

| PNGS 1 and 4 | 2 | 17,378 | 0 | N/A1 | 0 | 0 | 0.00 |

| PNGS 5–8 | 4 | 29,780 | 0 | 0 | 5 | 5 | 0.00 |

| Bruce A | 4 | 30,002 | 2 | 2 | 2 | 6 | 0.47 |

| Bruce B | 4 | 29,393 | 0 | 1 | 1 | 2 | 0.00 |

| Point Lepreau | 1 | 8,110 | 0 | 0 | 1 | 1 | 0.00 |

| Industry total | 18 | 138,184 | 2 | 3 | 10 | 15 | 0.10 |

1. Stepbacks are not a design feature at PNGS Units 1 and 4.

Figure 3 shows the total number of unplanned transients from 2015 to 2019 for the operating NPPs.

Figure 3 - Text version

| DNGS | PNGS 1,4 | PNGS 5-8 | Bruce A | Bruce B | Point Lepreau | Industry Total | |

|---|---|---|---|---|---|---|---|

| 2015 | 3 | 2 | 3 | 6 | 8 | 1 | 23 |

| 2016 | 5 | 3 | 2 | 9 | 3 | 2 | 24 |

| 2017 | 4 | 1 | 4 | 2 | 7 | 5 | 23 |

| 2018 | 4 | 3 | 12 | 6 | 2 | 0 | 27 |

| 2019 | 1 | 0 | 5 | 6 | 2 | 1 | 15 |

Figure 4 shows the number of unplanned reactor trips for Canada’s operating NPPs per 7,000 hours of operation. The 2019 data for the individual NPPs are provided in table 4. The unplanned total scrams is a WANO indicator defined as the number of unplanned automatic scrams (reactor protection system logic actuations, which are comparable to unplanned reactor trips in the Canadian context) that occur per 7,000 hours of critical operation (which is approximately one year of operation) for an individual reactor. WANO establishes two targets for this parameter for each type of reactor design. The individual target is the minimum target for individual reactors to meet, while the industry target is a more aggressive target used to assess the collective performance of reactors operated by all WANO members. WANO’s targets include ones for pressurized heavy water reactors (PHWRs), which, according to the regulatory oversight report for 2018 [2], would be the appropriate benchmarks for the CANDU reactors. However, CNSC staff have used the more aggressive target for pressurized water reactors (PWRs) for comparison in figure 4, superimposing a line representing WANO’s industry target (0.5 scrams per 7,000 hours critical) for PWRs. Figure 4 indicates that Canadian NPPs have been collectively well within that target since 2015. It is also clear that they would compare even more favourably against the WANO industry target for PWHRs.

To put the Canadian data in context, WANO reported that 72% of reactors worldwide met WANO’s industry target for their respective reactor type in 2019.

Figure 4 - Text version

| 2015 | 2016 | 2017 | 2018 | 2019 | |

|---|---|---|---|---|---|

| Canada | 0.15 | 0.20 | 0.20 | 0.26 | 0.10 |

Reporting and trending

The General Nuclear Safety and Control Regulations outlines specific scenarios under which licensees must file a report to the CNSC. For every reportable event, the licensees must file an event report that provides details regarding the event, including effects on the environment, the health and safety of persons, and the maintenance of security that have resulted or may result from the situation. Corrective actions that the licensees have taken or propose to take with respect to the reportable event must also be included. In 2019, CNSC staff observed that licensees performed all required follow-up on all events and included corrective actions and root cause analyses when appropriate.

Besides requirements for NPP licensees to submit quarterly reports on operations and safety performance indicators, REGDOC-3.1.1 also expands on event reporting requirements in the regulations and specifies requirements for other quarterly and annual reports to the CNSC.

WMF licensees are required to submit annual reports on operations as described in REGDOC-3.1.2. In addition, OPG is required by conditions in the WFOLs to provide a quarterly operations report for all 3 WMFs. Similar to REGDOC-3.1.1, this regulatory document also expands on event-reporting requirements for non-power reactor Class I nuclear facilities and for uranium mines and mills.

Outage management performance

During the planned outages in 2019 for all units of operating NPPs, CNSC staff conducted inspections to confirm that regulatory requirements were met and outages were executed safely. All planned and unplanned (forced) outages were followed up appropriately by licensees’ personnel. Through regular status reports on NPPs, CNSC staff informed the Commission about all unplanned outages resulting from reactor trips and associated follow-up in 2019.

Safe operating envelope

CNSC staff determined that all licensees of operating NPPs had adequate safe operating envelope (SOE) programs in 2019. The licensees implemented a hierarchy of documents to support production, updates and maintenance of SOE-related documentation. CNSC staff also determined that all licensees operated within their SOEs in 2019.

Severe accident management and recovery, and accident management and recovery

The second version of REGDOC-2.3.2, Accident Management, provides updated regulatory requirements for accident management at reactor facilities. All operating NPP licensees have implementation plans for REGDOC-2.3.2.

In 2019, licensees continued to update their severe accident management guidelines (SAMGs) to incorporate post-Fukushima lessons learned, including the addition of guidelines and strategies to deal with multi-unit events for multi-unit NPPs, events in irradiated fuel bays and events during shutdown states. CNSC staff also continued their review of the severe accident management programs for the DNGS and Bruce A and B.

2.4 Safety analysis

Deterministic safety analysis

In 2019, the NPP licensees continued their safety analysis improvement programs, which include revisions to their facility descriptions and safety analysis reports, in support of the staged implementation of REGDOC-2.4.1, Deterministic Safety Analysis. CNSC staff were satisfied with the progress in 2019 and provided recommendations to the licensees on their ongoing safety analysis improvements. The existing deterministic safety analyses remained adequate during the continued implementation of REGDOC-2.4.1 throughout 2019.

Safety analysis updates in 2019 included those needed to reflect changing reactor conditions, such as the aging of components. The licensees of operating NPPs also submitted to the CNSC specific analyses associated with refurbishment projects and IIPs. Section 3 provides examples.

Large-break loss-of-coolant accidents (LBLOCAs) are analyzed to demonstrate sufficient safety analysis margins for the limiting break size. OPG, NB Power and Bruce Power had proposed the composite analytical approach (CAA) to demonstrate that safety analysis margins for LBLOCA were larger than those evaluated using the traditional safety analysis method that is based on a limit-of-operating-envelope approach. They also intended to use CAA to justify the reclassification of some LBLOCA events as beyond-design-basis accidents by demonstrating the very low frequency of those events. CNSC staff deemed the proposed CAA methodology to be consistent with the requirements in REGDOC-2.4.1.

In 2019, CNSC staff accepted a CAA submission from Bruce Power that demonstrated the low frequency of pipe breaks above a threshold break size (TBS). See section 3.5.4 for details.

UPDATE: In January 2020, Bruce Power submitted a revised LBLOCA analysis and requested that LBLOCA events involving breaks larger than the TBS be reclassified as beyond-design-basis accidents.

OPG continued to support the industry efforts in its resolution of safety analysis margins for LBLOCAs using the CAA as part of its long-term plan. Section 3.1.4 details on OPG’s short-term approach.

NB Power continued to cooperate with Bruce Power in 2019 on the generic aspects of the CAA project and may consider a CAA-based analysis in the future.

Probabilistic safety assessment

REGDOC-2.4.2, Probabilistic Safety Assessment (PSA) for Nuclear Power Plants, published in May 2014, introduced requirements that had not been in its predecessor CNSC regulatory document, S-294, also called Probabilistic Safety Assessment (PSA) for Nuclear Power Plants. Examples of the new requirements in REGDOC-2.4.2 are considerations of multi‑unit impacts; combinations of hazards; plant operational states other than the at‑power and shutdown states; and other radioactive sources including the irradiated fuel bays. Point Lepreau has been compliant with REGDOC-2.4.2 since 2016.

In 2019, the DNGS, PNGS and Bruce A and B continued to comply with CNSC regulatory document S-294. The DNGS and PNGS continued to make progress with their implementation plans to comply with REGDOC-2.4.2 requirements by 2020. Bruce Power submitted PSA reports in 2019 to demonstrate compliance with the REGDOC‑2.4.2 requirements, which CNSC staff were reviewing at the end of 2019.

CNSC staff noted that OPG and Bruce Power were addressing the additional requirements outlined in REGDOC-2.4.2 through:

- PSA – for the consideration of multi-unit impacts

- other analysis methods, as allowed by REGDOC-2.4.2 – such as screening and bounding analyses, for the consideration of combinations of external hazards, other plant operational states, and other radioactive sources such as the irradiated fuel bays

The licensees were also participating in CANDU Owners Group projects to address REGDOC-2.4.2 requirements. Table 5 summarizes the status of PSAs at the operating NPPs in 2019.

| PSA submission | DNGS | PNGS 1 and 4 | PNGS 5–8 | Bruce A | Bruce B | Point Lepreau |

|---|---|---|---|---|---|---|

| Last PSA report received | 2015 | 2018 | 2017 | 2019 | 2019 | 2016 |

| Review status | Completed | Completed | Completed | Ongoing* | Ongoing* | Completed |

| Next PSA report expected | 2020 | 2023 | 2022 | 2024 | 2024 | 2021 |

| Expected compliance REGDOC-2.4.2 | 2020 | 2020** | 2020** | 2019 | 2019 | 2016 |

* CNSC staff planned to complete their review in 2020.

** OPG made a commitment to provide to the CNSC, by the end of 2020, updates for Pickering Units 1 and 4 and Pickering Units 5–8. The updates would focus solely on the additional updated requirements of REGDOC-2.4.2 that go beyond S‑294 requirements, including, for example, risk assessments of the irradiated fuel bay and other less significant risk contributors.

In addition to addressing the newFootnote 3 requirements in REGDOC-2.4.2, NPP licensees have also worked collaboratively to address direction from the Commission to OPG (associated with the renewal of the operating licence for the PNGS in 2013) to develop an approach for whole-site PSA. Whole-site PSA involves estimating aggregate risk for sites with multiple reactors and other radioactive sources. OPG submitted the whole-site PSA for the PNGS in 2017 [RIB 17557, item ii]. Bruce Power submitted its whole-site PSA methodology in 2018 [RIB 14760] and submitted the aggregated risk values for whole-site PSA for Bruce A and B in April 2019 [RIB 14759]. CNSC staff completed the review in 2019. Based on the information submitted, CNSC staff acknowledged that the submissions provided a good characterization of the whole-site risk for Bruce A and B.

OPG submitted a whole-site, aggregated risk value for the DNGS in 2015. As part of a whole-site PSA for the DNGS, OPG was planning a risk aggregation calculation in 2020 based on the simplified aggregation method that was used for the PNGS and the available results from the DNGS PSA.

As part of the action [RIB 8504] on CNSC staff to provide an update to the Commission on the activities associated with the establishment of a proposed regulatory position on risk aggregation, staff provided the Commission with an update in December 2017 on whole-site PSA [3]. The update included a presentation on staff’s active role in the international effort, especially with the International Atomic Energy Agency (IAEA) and the Nuclear Energy Agency (NEA), and on site-level PSA (including multi-unit PSA) developments such as risk aggregation. The NEA work on the status of site-level PSA developments was completed in December 2018, and the NEA planned to issue the final report in 2020. The IAEA project on multi-unit PSA (MU-PSA) was completed, including its Phase 3 “Review of the MU-PSA Methodology in Light of the Lessons Learnt From the Phase 2 Case Study.” The IAEA was proceeding to publish it as part of the IAEA Safety Report Series.

Both the NEA and IAEA projects reiterated that the scope of risk aggregation is highly dependent on the regulatory requirements, as well as on the intended uses and applications of the PSA. CNSC staff’s position with regard to risk aggregation is further elaborated in section 4.2.2, “Guidance,” of REGDOC-2.5.2, Design of Reactor Facilities: Nuclear Power Plants, and remains valid. Section 4.2.2 states the following:

It is recognized that when the risk metrics for external events are conservatively estimated, their summation with the risk metrics for internal events can lead to misinterpretation. Should the aggregated total exceed the safety goals, conclusions should not be derived from the aggregated total until the scope of the conservative bias in the other hazards is investigated.

Severe accident analysis

In 2019, the licensees of operating NPPs continued their severe accident analyses to support PSA Level 2 analysis for the evaluation of plant safety goals, in order to demonstrate the effectiveness of their severe accident management programs and to support severe accident drills and exercises for emergency preparedness and response.

NB Power submitted an updated PSA Level 2 methodology and continued to work on the update of PSA Level 2 analysis. In this updated methodology, a large set of severe accident analyses (using the recently updated severe accident computer code MAAP5-CANDU) was defined and planned for supporting the evaluation of safety goals for Point Lepreau. CNSC staff found NB Power’s methodology for MAAP5-CANDU simulations acceptable.

In 2019, CNSC staff were reviewing the severe accident analysis of the Bruce Power and OPG NPPs in support of their Level 2 PSAs. CNSC staff planned to complete the reviews in 2020.

Management of safety issues (including R&D programs)

CANDU safety issues

CNSC staff continued to monitor the management of CANDU safety issues (CSIs) by licensees of operating NPPs to ensure timely and effective implementation of plant-specific safety improvement initiatives and risk control measures. In 2019, there were 4 remaining Category 3 CSIs, 3 of which are related to LBLOCA:

- AA9 – analysis for void reactivity coefficient

- PF9 – fuel behaviour in high temperature transients

- PF10 – fuel behaviour in power pulse transients

The different categories of CSIs are described in General Description of Regulatory Framework for Nuclear Power Generating Sites [1]. As noted above, the licensees of operating NPPs continued to develop the CAA methodology in order to address the LBLOCA CSIs. Through an industry-wide agreement, Bruce Power was taking the lead in the regulatory application of the CAA methodology. In 2019, progress was made on long-standing work on the reclassification of the CSIs related to LBLOCA.

For Bruce Power, CNSC staff reviewed the submission related to the CAA for LBLOCA, TBS assessment and additional information in support of the CAA. Subsequently, in November 2019, CNSC staff accepted Bruce Power’s request for reclassification of the 3 LBLOCA CSIs (AA9, PF9 and PF10) from Category 3 to Category 2.

Work in this area by the other licensees was ongoing, and the licensees were expected to submit requests for the reclassification of these CSIs once their analyses were completed.

Remaining Category 3 CSI

The fourth Category 3 issue, IH6, is related to the systematic assessment of the effects of high-energy pipeline breaks inside containment. At the beginning of 2019, this issue only applied as a Category 3 CSI to PNGS Units 1–4 and Point Lepreau. (For PNGS Units 5–8, CNSC staff had reclassified CSI IH6 from Category 3 to Category 2 in 2018.)

For PNGS Units 1–4, in November 2019 CNSC staff completed their review of OPG’s request pertaining to reclassification of CSI IH6. Based on OPG’s response to CNSC staff’s request for additional information and clarification, OPG’s reclassification request was granted. However, this reclassification was conditional on OPG providing further assurance of the actual condition of the non-nuclear, high-energy pipelines inside containment.

For Point Lepreau, CNSC staff reviewed NB Power’s report on CSI IH6 analysis and, in January 2019, reclassified CSI IH6 from Category 3 to Category 2.

Reclassification of CSI AA3

CSI AA3, on computer code and plant model validation, had previously been reclassified from Category 3 to Category 2. As part of ongoing activities to address residual issues related to CSI AA3, the licensees of operating NPPs had contributed to the revision of the CANDU Owners Group (COG) guidelines on code validation and code accuracy assessment, as described in the regulatory oversight report for 2018 [2]. The licensees were also addressing other areas that needed further improvements to meet the objectives of the computer code and plant model validation program associated with CSI AA3. In 2019, the licensees provided a status update on the remaining work related to CSI AA3 and requested the closure of the associated action items. At the end of 2019, CNSC staff’s review was in progress.

R&D programs

In 2019, CNSC staff continued to undertake systematic evaluations to confirm that the industry maintains or has access to a robust R&D capability to address emerging issues and enhance knowledge and confidence in safety provisions in key areas.

The licensees continued to participate in COG R&D and joint project programs, in collaboration with both national and international stakeholders, which included ongoing monitoring, review and maintenance of R&D capability.

In 2019, all licensees submitted their 2018 COG R&D annual reports, which included:

- annual COG R&D program overview reports and operational plans

- multi-year strategic plans and capability maintenance reviews

The COG R&D program included the following 5 base program areas and the strategic R&D program:

- fuel channels

- safety and licensing

- health, safety and environment

- chemistry, materials and components

- Industry Standard Toolset

These programs aimed to support the safe, reliable and efficient operation of CANDU reactors in the short and long term. Their main objectives included the following:

- provide qualitative and quantitative experimental data to demonstrate key phenomena during the late phase of a postulated severe accident

- develop a consistent set of minimal requirements for the assessment of doses

- develop and demonstrate the effectiveness of various mitigation features in containment

- support the industry in increasing safety margins in CANDU stations in all operational states

- provide a database for use in industry tool set computer codes

2.5 Physical design

In 2019, each licensee carried out various modifications to improve the overall performance of its facilities and improve safety in design and operations. There were no impacts on the licensees’ abilities to operate within their safety cases while they made these changes.

Design governance

In 2019, CNSC staff reviewed the licensees’ updates of their fire protection programs and fire protection assessments and confirmed that they complied with the applicable fire protection requirements.

System design

In 2019, CNSC staff confirmed that the licensees’ electrical power systems (EPSs) and instrumentation and control (I&C) functioned as expected.

Components design

Licensees of operating NPPs have mature fuel design and inspection programs.

Over the past several years, operating NPPs have experienced challenges related to fuel performance (such as fuel defects or fuel bundle vibrations). However, licensee fuel programs and personnel have adequately managed these challenges. Licensees have met regulatory limits for fuel bundle and fuel channel power throughout this period. Fuel performance has returned to historic norms, with the remaining challenges having mitigation strategies in place or in development. CNSC staff continued to monitor the status of the mitigation strategies and were satisfied with the licensees’ management of these issues in 2019. Section 3 provides details on individual licensee challenges and performance.

The licensees of operating NPPs have cable condition monitoring and surveillance programs that are verified through compliance activities to ensure their effectiveness in supporting safe and reliable operations. CNSC staff were satisfied with the licensees’ management of these programs in 2019.

2.6 Fitness for service

Equipment fitness for service / equipment performance

The licensees of operating NPPs monitor the performance or condition of the special safety systems (SSSs) against unavailability targets (no higher than 0.001) to ensure that these systems are capable of fulfilling their intended functions. Overall, the SSSs performed well in 2019 and met their unavailability targets, with some exceptions as outlined in section 3.

The licensees also monitored missed tests of systems important to safety. Table 6 and figure 5 show data for the operating NPPs and “the industry” as a whole.

The number of total missed safety system tests remained very low in 2019. In all, 47,244 tests were performed and the fraction of missed tests was 0.01%. The impact of missing a single test is negligible because the NPP designs have sufficiently high redundancy to ensure continuous availability of the safety systems. Table 6 indicates that 5 tests of SSSs were not fully completed before the due date.

| Nuclear power plant | Number of annual planned tests | Safety system tests not completed | Percent not completed | |||

|---|---|---|---|---|---|---|

| Special safety systems | Standby safety systems | Safety-related process systems | Total | |||

| DNGS | 10,381 | 3 | 1 | 1 | 5 | 0.05 |

| PNGS | 14,318 | 0 | 0 | 0 | 0 | 0.00 |

| Bruce A | 9,628 | 0 | 0 | 0 | 0 | 0.00 |

| Bruce B | 8,824 | 0 | 0 | 0 | 0 | 0.00 |

| Point Lepreau | 4,093 | 2 | 0 | 0 | 2 | 0.05 |

| Industry total | 47,244 | 5 | 1 | 1 | 7 | 0.01 |

.jpg/object)

Figure 5 - Text version

| DNGS | PNGS | Bruce A | Bruce B | Point Lepreau | Industry total | Industry % missed tests | |

|---|---|---|---|---|---|---|---|

| 2015 | 0 | 0 | 0 | 3 | 7 | 10 | 0.02% |

| 2016 | 0 | 2 | 2 | 0 | 1 | 5 | 0.01% |

| 2017 | 1 | 0 | 3 | 0 | 1 | 5 | 0.01% |

| 2018 | 0 | 5 | 1 | 0 | 0 | 6 | 0.01% |

| 2019 | 5 | 0 | 0 | 0 | 2 | 7 | 0,01% |

In 2016, OPG initiated a joint fuelling machine reliability project with NB Power through COG with the aim of preventing premature failures of the fuelling machine ram seals. Following engineering, testing and manufacturing, OPG received new (type IV) ram seals, housings and sleeves in 2019 for Pickering Units 5–8. OPG completed the initial installation (Unit 8 West) on December 27, 2019 [RIB 17557, item iii].

UPDATE: OPG completed the next installation (Pickering Unit 7 East) on April 30, 2020. The 2 fuelling machines with replaced seals had fuelled hundreds of fuel channels without experiencing any performance issues. OPG was proceeding with the installation of the new seals for the remaining fuelling machine rams for Units 5–8. OPG also expected to receive additional materials to service rams for Pickering Units 1 and 4 by the end of August 2020.

Maintenance

The preventive maintenance completion ratio quantifies the effectiveness of the preventive maintenance program in minimizing the need for corrective maintenance activities for safety-related systems. The average preventive maintenance completion ratio value for operating NPPs was 94% in 2019. CNSC staff were satisfied with the effectiveness of the licensees’ preventive maintenance.

The corrective maintenance backlogs, deficient maintenance backlogs and deferrals of preventive maintenance are also used to monitor the effectiveness of the maintenance programs at NPPs. The corrective and deficient maintenance backlogs, as well as the deferrals of preventive maintenance, reported in this regulatory oversight report are for critical components, which are defined by the licensee as those that are significant in terms of plant safety and/or plant operation.

Table 7 shows the trends of the maintenance backlogs and deferrals for the industry. The industry average of these safety performance indicators continuously decreased or were kept low in 2019. Overall, CNSC staff were satisfied with the progress in 2019. The current levels of the maintenance backlogs and deferrals for critical components for the NPPs represent a negligible risk to the safe operation of the NPPs.

| Safety performance indicator | Average quarterly work orders per unit in 2017 | Average quarterly work orders per unit in 2018 | Average quarterly work orders per unit in 2019 | Three-year trending |

|---|---|---|---|---|

| Corrective maintenance backlog | 4 | 1 | 1 | down |

| Deficient maintenance backlog | 94 | 16 | 9 | down |

| Deferrals of preventive maintenance | 30 | 4 | 2 | down |

Aging management

Pressure tubes and fuel channels – Overall performance

With respect to the pressure tubes in operating NPPs, overall CNSC staff were satisfied that the lifecycle management plans (LCMPs) reflected sound aging management. CNSC staff also continued to review the results from fuel channel inspections that occurred routinely during planned inspection outages in 2019. They confirmed that no new flaw-initiation mechanisms were identified and that licensees appropriately evaluated any findings that required disposition, in accordance with CSA Group standards. CNSC staff concluded that fitness-for-service of inspected pressure tubes was effectively demonstrated.

CNSC staff were satisfied with the licensees’ work to ensure that fuel channel spacers continued to perform their design function in 2019. A review of available information confirmed that the spacers were behaving predictably.

CNSC staff have enhanced regulatory oversight for licensees’ activities to assess and manage the aging of fuel channels for units entering periods of extended operation. This increased focus on fuel channels is due to the fact that they are being operated beyond 210,000 effective full-power hours (EFPH) at some units. (Designers assumed 210,000 EFPH in order to establish the inspection requirements and acceptable levels of in-service degradation for CANDU pressure tubes.)

Recent developments and research in aging management

For in-service changes in pressure tube properties (such as fracture toughness), equivalent hydrogen (Heq) concentration is more important than EFPH. Fracture toughness is an important parameter that is modelled and used for assessments of leak-before-break and fracture protection of pressure tubes. For temperatures below 250 °C, Heq content in the pressure tube is a critical input to the fracture toughness model. The analytical fracture toughness model that the CNSC currently accepts for use in this temperature range is valid only up to a Heq concentration of 120 ppm.

The licensees continued R&D related to the modelling of fracture toughness of pressure tube material in 2019 as some operating reactors may reach a Heq concentration of 120 ppm before their planned shutdown or refurbishment. In addition, improvements related to the model and its applicability were needed to maintain confidence in its use.

CNSC staff consider that the current regulatory process to monitor additional validation of the existing fracture toughness model up to Heq of 120 ppm is adequate to ensure that the model will adequately support assessments mandated by the CSA Group standards. In preparation for units approaching the validity limit of the existing toughness model (120 ppm Heq in any pressure tube), licensees must also develop a revised toughness model (capable of predicting toughness beyond 120 ppm Heq) and submit the technical basis for CNSC staff’s approval well before any pressure tube reaches 120 ppm.

The licensees must seek CNSC staff concurrence (for the PNGS) or Commission approval (for Bruce A and B) to operate any pressure tube beyond 120 ppm Heq. Appendix C shows details on the current and anticipated future fuel channel conditions [RIB 14757, item ii] and validity of the fracture toughness model for the NPPs in Ontario.

In 2019, CNSC staff actively monitored the industry’s progress in research activities to ensure that licensees have sufficient understanding of degradation issues to safely operate pressure tubes, especially those planned for extended operation. Specifically, CNSC staff monitored the fuel channel life confirmation project, which included the following activities in 2019:

- research focusing on the fracture toughness of near-inlet areas of pressure tubes and changes in toughness occurring as Heq levels exceed 120 ppm [RIB 14757, item i]

- collection of additional pressure tube burst-test data, supporting development of a revised version of the fracture toughness model [RIB 14757, item i]

-

continued development of assessment methodologies:

- a probabilistic approach for demonstrating fracture protection (that is, confirmation that a pressure tube will continue to meet its design intent, if an undetected crack is subject to design-basis pressure/temperature transients)

- a fully deterministic approach for assessing the risk of cracking due to hydrided region overload (that is, when a hydrided area is exposed to greater stress than existed when it was initially created)

- continued development of an industry-standard set of fitness-for-service guidelines for Inconel X-750 (a.k.a. “tight-fitting”) annulus spacers

Overall, CNSC staff were satisfied with the licensees’ work to demonstrate and support the safe operation of pressure tubes in the near- and medium-term.

Chemistry control

Figures 6 and 7 show the values of the safety performance indicators “chemistry index” and “chemistry compliance index” for operating NPPs from 2015 to 2019. Based on these values, CNSC staff determined that chemistry control was acceptable for all licensees. The comparatively low results for the chemistry compliance index for Bruce A and B (figure 7) were due to a downward trend in moderator (heavy water (D2O)) isotopic purity for all units. However, there was no impact on the safe operation of Bruce A and B, and safety system functions were not impaired.

Figure 6 - Text version

| 2015 | 2016 | 2017 | 2018 | 2019 | |

|---|---|---|---|---|---|

| DNGS | 99.48 | 99.37 | 98.60 | 98.76 | 99.80 |

| PNGS 1,4 | 98.33 | 98.16 | 97.78 | 97.72 | 99.50 |

| PNGS 5-8 | 99.40 | 99.54 | 99.59 | 99.36 | 99.60 |

| Bruce-A | 95.58 | 93.95 | 99.30 | 98.61 | 99.30 |

| Bruce-B | 97.20 | 97.56 | 99.18 | 99.10 | 99.30 |

| Pt.Lepreau | 96.29 | 97.60 | 97.88 | 98.25 | 98.10 |

Figure 7 - Text version

| 2015 | 2016 | 2017 | 2018 | 2019 | |

|---|---|---|---|---|---|

| DNGS | 99.99 | 99.97 | 100.00 | 99.59 | 100.00 |

| PNGS 1,4 | 99.81 | 99.96 | 99.59 | 99.81 | 99.97 |

| PNGS 5-8 | 99.97 | 99.99 | 99.63 | 99.98 | 99.98 |

| Bruce-A | 92.55 | 92.87 | 93.33 | 94.12 | 95.90 |

| Bruce-B | 97.81 | 96.55 | 94.33 | 95.17 | 93.40 |

| Pt.Lepreau | 98.75 | 99.38 | 98.72 | 96.91 | 99.10 |

Periodic inspections and testing

The licensees of operating NPPs are developing periodic inspection programs that comply with CSA N285.7, Periodic Inspection of CANDU Nuclear Power Plant Balance of Plant Systems and Components, which will be adopted as compliance verification criteria in the future for all operating NPPs except the PNGS. Implementation of a program for N285.7 was not practical for the NGS, given the planned shutdown in 2024. However, CNSC staff planned to apply experience gained from its implementation at other NPPs to the PNGS, in order to address potential safety concerns should the need arise.

2.7 Radiation protection

Application of ALARA (as low as reasonably achievable)

In 2019, the total collective dose for monitored individuals at all Canadian NPPs and WMFs was 20.4 person-sieverts (p-Sv), approximately 21% lower than the industry-wide collective dose reported for 2018 (25.9 p-Sv). The number of persons who received a reportable dose in 2019 (9,857) was slightly higher than 2018 values (9,792). The decrease in total collective dose was mainly due to a reduction in high-dose refurbishment activities at the DNGS.

The vast majority of collective doses for the NPPs and WMFs occurs at the operating NPPs. Table 8 shows the collective doses for the individual NPPs. It illustrates that outages (including refurbishment activities) accounted for a much greater fraction of the collective dose than routine operations and that external dose was, collectively, much greater than internal dose.

| NPP | Routine operations | Outages | Internal | External | Total |

|---|---|---|---|---|---|

| DNGS | 394 | 7,263* | 469 | 7,188* | 7,657* |

| PNGS | 869 | 2,216 | 652 | 2,433 | 3,085 |

| Point Lepreau | 224 | 372 | 156 | 440 | 596 |

| Bruce A | 336 | 4,725 | 262 | 4,798 | 5,061 |

| Bruce B | 575 | 4,100 | 297 | 4,377 | 4,674 |

* For 2019, only the DNGS had dose attributed to refurbishment activities.

Figures 8, 9, and 10 present the effective doses (average and maximum) and dose distributions to monitored persons, based on the dose records provided to the CNSC by the NPPs and WMFs for 2015 to 2019.

Figure 8 shows that, for 2019, the average effective dose at each NPP and WMF ranged from 0.23 to 3.07 mSv per year. In general, the fluctuations in average dose observed from year to year reflect the type and scope of work being performed at each facility. No negative trends were identified in 2019. The annual average effective dose in 2019 for all Canadian NPPs was 2.07 millisieverts (mSv), an approximate decrease of 21.5% from the 2018 value of 2.64 mSv.

Figure 8 - Text version

| DNGS | PNGS | Point Lepreau | Bruce A&B | Gentilly-2 | WWMF | DWMF | PWMF | |

|---|---|---|---|---|---|---|---|---|

| 2015 | 1.18 | 2.31 | 0.70 | 2.78 | 0.11 | 0.30 | 0.50 | 0.40 |

| 2016 | 1.42 | 2.00 | 1.20 | 3.51 | 0.01 | 0.30 | 0.50 | 0.40 |

| 2017 | 3.24 | 1.75 | 0.80 | 2.56 | 0.37 | 0.30 | 0.50 | 0.40 |

| 2018 | 2.67 | 2.06 | 1.3 | 3.47 | 0.31 | 0.40 | 0.30 | 0.60 |

| 2019 | 1.93 | 1.45 | 0.76 | 3.07 | 0.23 | 0.60 | 0.20 | 0.40 |